Pharma Manufacturing 4.0: A Career Road Map Modern Skills & Tools That Will Boost Your Growth In the Industry

The Pharmaceutical Industry is evolving faster with Pharma Technology and Digital Pharma tools. Earlier, the industry used to depend more on manual processes and paper-based systems, but now the industry is powered by automation, real-time data, AI, and connected machines. This transformation of the pharma industry is often referred to as Pharma Manufacturing 4.0, which is a modern, smarter way of making medicine that is safer, faster, and more efficient than ever before.

For pharma professionals, understanding these technologies is essential as it has become the new baseline for career growth in manufacturing, QA, QC, R&D, and supply chain roles.

This guide will help you to learn about the key concepts like Digital Twins, IoT, Continuous Manufacturing, and automated batch records, so that you can understand what is changing in the industry and how you can prepare for it.

Why Pharma Manufacturing 4.0 Matters Right Now

The pharma industry worldwide is now shifting to smart manufacturing as it helps them with the following:

- In reducing errors and deviations

- To improve the Product quality

- For Speeding Up the Production

- To lower the costs

- To make sure compliance with regulators like the USFDA, EMA, and CDSCO

- For responding faster during emergencies(e.g., Vaccine manufacturing during the COVID situation)

Digital Twins: The Virtual Copy of The Entire Manufacturing Plant

What are Digital Twins?

A Digital Twin is a virtual model of a real manufacturing system, like a Production line, equipment, or even an entire facility. It represents what is happening in real time and can also predict problems before they happen.

For example, if a machine is about to have a breakdown, instead of waiting until it fails, the digital twin will warn you before.

Where it’s Used in Pharma

- For optimizing equipment cleaning cycles

- To predict machine failures

- In testing the new manufacturing processes virtually

- For monitoring environmental conditions in sterile areas

- In Improving scale-up from R&D to full production

Skills You Need

- Understanding of equipment and processes in basic level at least

- Ability to read dashboards and interpret the data

- Familiarity with simulation tools, like Siemens, AVEVA, and AspenTech

Why it Matters for Your Career

Digital Twins are now becoming the standard in major pharma manufacturing plants. It’s very important to understand how they work, which will make you more valuable in production, engineering, and validation roles.

2. IoT in Pharma Manufacturing

What is IoT?

Internet Of Things(IoT) simply means machines, sensors, and devices that can talk to each other and send data in real time.

How IoT works in Pharma

- The Sensors track humidity, temperature, pressure, and particle count

- Machines will report their health automatically

- Movement of the materials is monitored from the warehouse to the packaging

- Real-time alerts will be sent for the deviations

- The Process data will be collected for analysis continuously.

Real Examples

- Smart HVAC systems in sterile areas

- Automated temperature monitoring for vaccines

- IoT enables water systems(WFI, PW, Clean steams)

Skills You Need

- Understanding of sensors and basic automation

- Comfort working around SCADA, PLC, and MES interfaces

- Ability to analyze trends and alarms

Why it Matters

Companies now prefer candidates who can handle digital equipment and real-time monitoring systems, and not just manual processes.

3. Continuous Manufacturing

What is Continuous Manufacturing?

It is an advanced control system that allows the entire process from raw materials to final products to run continuously instead of making the medicines in batches.

Benefits

- It makes the production processes more efficient and faster

- The quality of the product will be consistent

- The deviations will be decreased

- The downtime will be decreased

- The control over the critical parameters will be improved

Where it’s used

- In Tablets and API Manufacturing

- In high-value medicines and Personalized or small-batch therapies

Regulators like the USFDA strongly support continuous manufacturing as it reduces risks and ensures more stable product quality.

Skills You Need

- Understanding of PAT ( Process Analytical Technology)

- Basics of automation and process control

- Working knowledge of material flow and real-time quality monitoring

Career Advantage

Companies like Pfizer, Novartis, and Cipla are scaling continuous manufacturing. Professionals with this New Pharma Technology knowledge will stand out in production, validation, and QA Jobs.

4. Automated Batch Records

Paper batch records often lead to human errors, deviations, and compliance challenges. Therefore, the companies are now using the eBR( Electronic Batch Records) as part of their Manufacturing Systems

How does the Electronic Batch Record work?

- It helps to eliminate manual writing

- It prevents missing signatures and data gaps

- The eBR shows real-time status of each batch

- It makes sure that actions are done in the correct sequence

- Helps in reducing investigations and CAPAs

Tools Used

- Werum PAS-X

- Rockwell PharmaSuite

- Emerson Syncade

Skills You Need

- Basic Understanding of MES

- Ability to operate digital interfaces

- Knowledge of GMP documentation

- Comfort with structured data entry

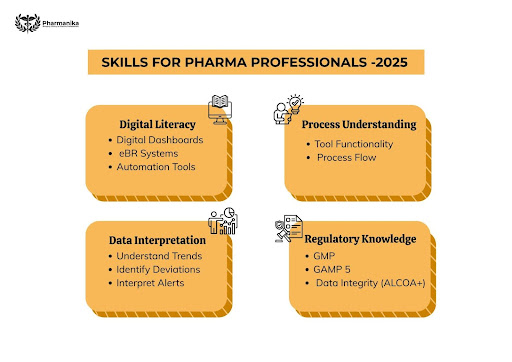

Skills Every Pharma Professional Should Build For 2025 and Beyond

- Digital Literacy

- Comfortable using Digital dashboards, eBR Systems, and automation tools.

- Data Interpretation

- For Data Interpretation, you don’t need to be a data scientist, but just be able to understand trends, deviations, and alerts

- Process Understanding

- Digital Tools are only as good as the person who understands them and the process

- Regulatory knowledge

- GMP+GAMP 5 + Data integrity (ALCOA+)

- Cross-Functional Communication

- Manufacturing 4.0 requires teamwork between the production, engineering, QA, IT, and automation.

How students can prepare early

- Take a short course in automation, IoT basics, and manufacturing quality systems

- Learn MES or SCADA Fundamentals

- Regularly follow pharma tech News

- Pursue internships in manufacturing plants to observe real systems

- Try Building confidence with Digital tools like Excel, Dashboards, and basic data analysis

How Working Professionals Can Upgrade

- Learn the digital Pharma tools that are used in your manufacturing plant

- Understand how the sensors and automation interact with batch data

- Participate in digital Pharma transformation and paperless initiatives at your workplace

- Update your resume with the skills required for Pharma Industry 4.0

- Take recognized certifications (available in Biotecnika.org)

Pharma manufacturing 4.0 is not just science fiction anymore, but it is happening now, and the companies are now actively looking for professionals who can work with modern pharma technology and automated systems.

If you’re a pharma professional looking to advance your career, with the right skills, you can shift your career to the next level.

Pharmanika aims to simplify these complex industry trends. So you can stay updated, stay skilled, and stay ahead.