Quality Assurance and Quality Control Guidelines in Pharma

The Pharmaceutical industry occupies a significant position in healthcare globally because it delivers medicines that help in preventing, managing, and curing diseases. In the Complex world of Pharmaceuticals, a minute error can jeopardize human lives. Have you ever wondered how manufacturing processes ensure that they are safe, and who is responsible for the safety of the products or processes? The Quality Assurance (QA) and Quality Control (QC) can be said as the guardians of Pharmaceutical integrity because the pharmaceutical industry relies on the back of the QA and QC systems. Both QA and QC Guidelines contain rules that ensure that the manufacturing processes adhere to Good Manufacturing Practice and Standard Operating Procedures (SOPs).

The QA is a process-oriented system while QC is a product-oriented system, and to support these systems, the international and national regulatory authorities have set some guidelines. These are called QA and QC guidelines to ensure that the manufacturing of product is consistent with regular quality checks, testing and distribution throughout the process.

In this article, we will discuss the Quality Control and Quality Assurance Guidelines and their role in the Pharma Industry, and the career opportunities they offer to enhance quality and compliance.

Role in the Pharma Industry

The Pharma Industry handles life saving products, and the quality of the product is not negotiable because many lives depend on it. Quality Assurance and Quality Control work side by side but distinctly. The Quality Assurance ensures that there is no error in the entire process. They check every step, from the raw material processing to the final packaging and distribution, to the manufacturing systems. They will design and implement SOPs for every step and do quality testing, manufacturing processes that follow GMP, ICH Standard Guidelines, maintain batch records, deviation reports, and other documents, so that in case of a product issue or recall, they can trace it.

The Quality Control system performs testing and inspection of the pharmaceutical active ingredient used to make the product, to ensure quality. They will monitor critical manufacturing stages and conduct physical, chemical, and microbiological tests on the initial and final product. They will check for product stability, determine shelf life, and storage conditions.

The Quality Assurance and Quality Control Guidelines are the backbone of the Pharma industry because the products they manufacture directly impact human life. These guidelines are crucial to follow so that the development and manufacturing align with the standards and safeguard patient safety.

What are the Guidelines?

Quality Assurance Guidelines

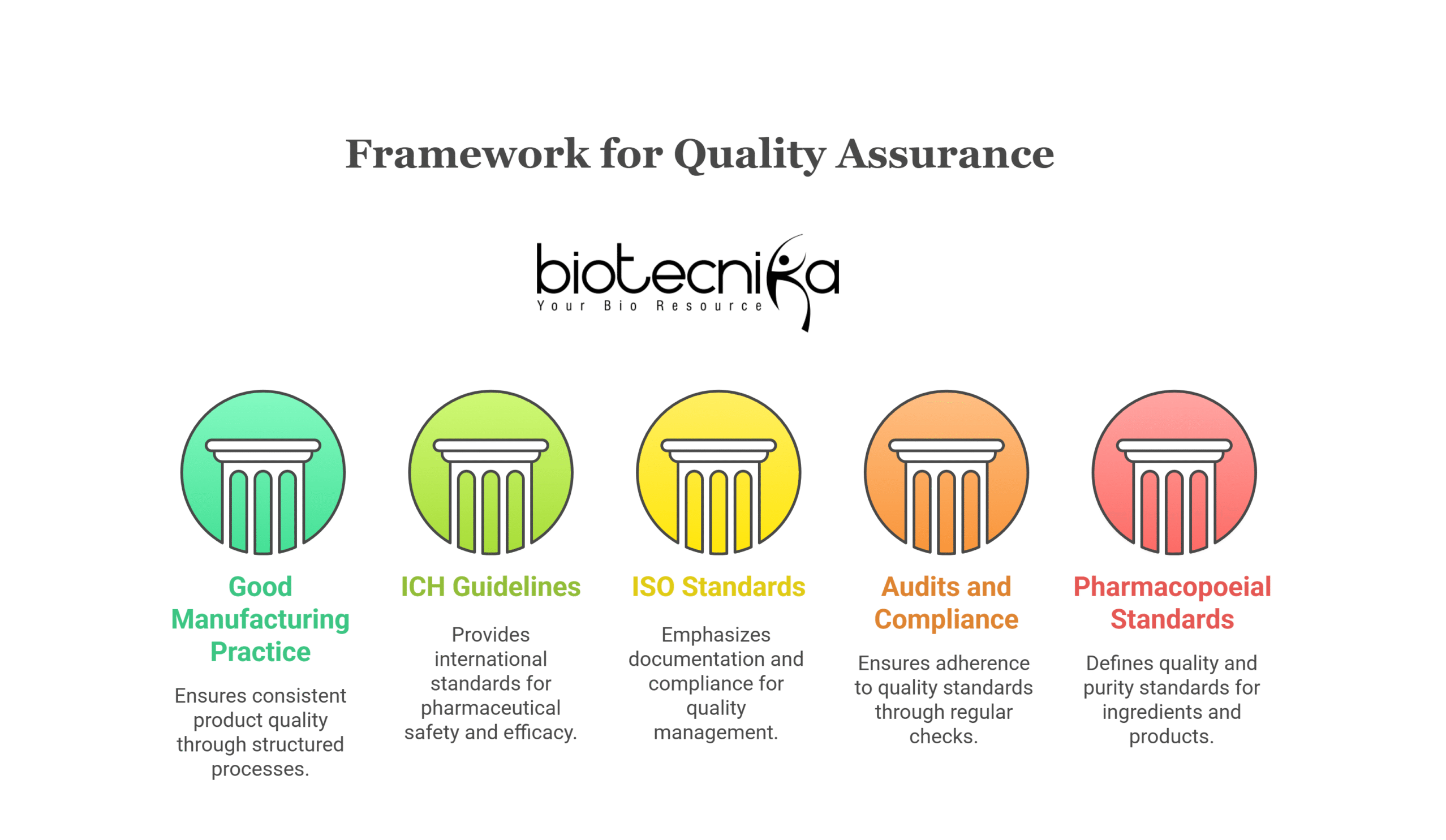

These are a set of structured standard instructions that are designed to ensure the product’s quality while it is produced through machines and processes. The following are the Guidelines:

Good Manufacturing Practice (GCP)

- They ensure that the facilities, processes, and equipments are designed in such a way that the product is produced consistently with quality standards.

- They prevent errors throughout the manufacturing process and provide a strong framework of documentation.

International Council for Harmonisation (ICH) Guidelines

These are an internationally recognized set of rules made by the International Council for Harmonisation, and are responsible for the safety and efficacy of the pharma products. The Following are the ICH Guidelines followed by QA.

- ICH Q8: They are the guidelines to understand the pharmaceutical product development and its process.

- ICH Q9: They help in quality risk management and identify and solve the issue.

- ICH Q10: It is also called the Pharmaceutical Quality System guidelines, which gives a framework to ensure the management of quality throughout the processes.

ISO (International Organization of Standardization) standards

- ISO 9001: It emphasizes documentation and compliance and helps in monitoring the process to manage deviation and implement corrections and preventive actions.

- ISO 13485: It provides quality management of pharma products for medical devices.

Audits and Compliance Checks

Regular audits and internal inspections are done as part of the QA guidelines to ensure quality throughout the process.

Quality Control Guidelines

These are another set of standard, structured rules that are designed to ensure the product’s safety, durability, shelf life, and the chemical ingredient’s purity. The following are the Quality Control Guidelines:

Pharmacopoeial Standards

These are a set of official rules and guidelines that define the quality, strength, identity and purity of the ingredients and the final products. These are USP (United States Pharmacopeia), BP (British Pharmacopeia), EP (European Pharmacopeia), and IP (Indian Pharmacopeia) are standards that define the testing and requirements of raw materials, active ingredients, and final products, which include the dissolution rates, purity, and the percentage of allowed impurities. QC laboratories mostly rely on these standards for testing.

Good Manufacturing Practice

They support the QA system by documenting the operations, cleanliness, calibrated equipment, and proper handling of materials.

International Council for Harmonisation (ICH) Guidelines

ICH Q2 and ICH Q7 ensure accuracy, precision, and strength of the methodology, and requirements of active ingredients, respectively.

ISO standards

ISO 9001 and ISO 13485 emphasize making robust practices for management, and the latter is for medical devices to ensure their compliance with quality and safety standards.

QA and QC guidelines are the twin pillars of the Pharmaceutical Industry. QA ensures all the processes from manufacturing to packaging follow all standard guidelines and SOPs to ensure no errors, documentation of the processes for future reference, and QCs are responsible for checking the quality of the product by testing the raw materials, like the active pharmaceutical ingredients, and the final product, and ensuring they follow Pharmacopoeial Standards. It is because of them that people trust the pharmaceutical industry’s products to be safe. They are the guardians of the pharma industry as they ensure safe drug delivery to the people and contribute to the medicinal, technology, and food sectors.